Sales office and service Gdansk: +48 58 320 13 05 | Sales office Warsaw: +48 504 060 713 | PL | EN

Sales office and service Gdansk: +48 58 320 13 05 | Sales office Warsaw: +48 504 060 713 | PL | EN

Imer Machinery >> Imer Truck Mixers >> ORU LT 9.7H + SL version

Imer Truck Mixers ORU LT 9.7H + SL version

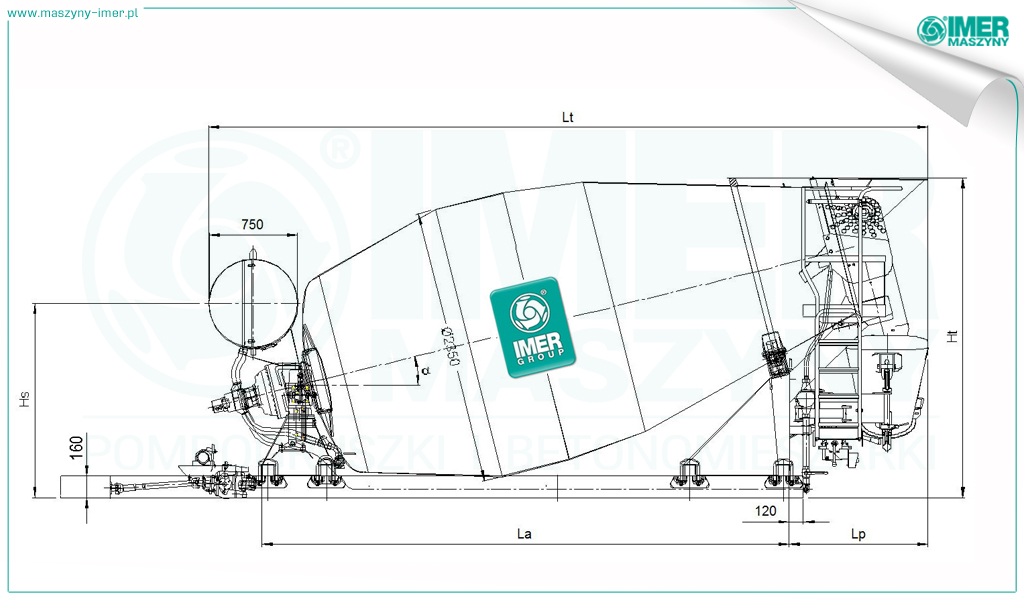

The most popular LT 9.7H concrete mixer with a nominal volume of 9m3 is a compromise between capacity and weight. Specially designed spiral and shovels, optimise the loading and unloading process and ensure the homogeneity of the concrete. We have designed the components of the concrete mixer to achieve the best geometry and to ensure maximum efficiency and functionality during the loading phase, minimising the risk of plugging the hopper section. Of course, safety as well as operator convenience have not been overlooked. The concrete mixer body is available in standard and superlight versions.

In the standard version, the drum walls are made of abrasion-resistant 30MnB5 steel with a thickness of 4mm. The same steel is used for the mixing spirals. In the SL version, on the other hand, the walls are made of IMER WEAR Raex 300 steel with a thickness of 3mm and the spirals of IMER WEAR Raex 450. This has reduced the weight by more than half a tonne. The drum is rotated by a two-stage planetary gearbox, which is driven by a variable displacement hydraulic pump. Oil is cooled by a powerful radiator with a built-in reservoir. The body has a pressurised steel water tank with a capacity of 400 or 650l. The water system additionally has a water meter with a scale from 0 to 500 litres.

Imer Truck Mixers ORU LT 9.7H + SL version

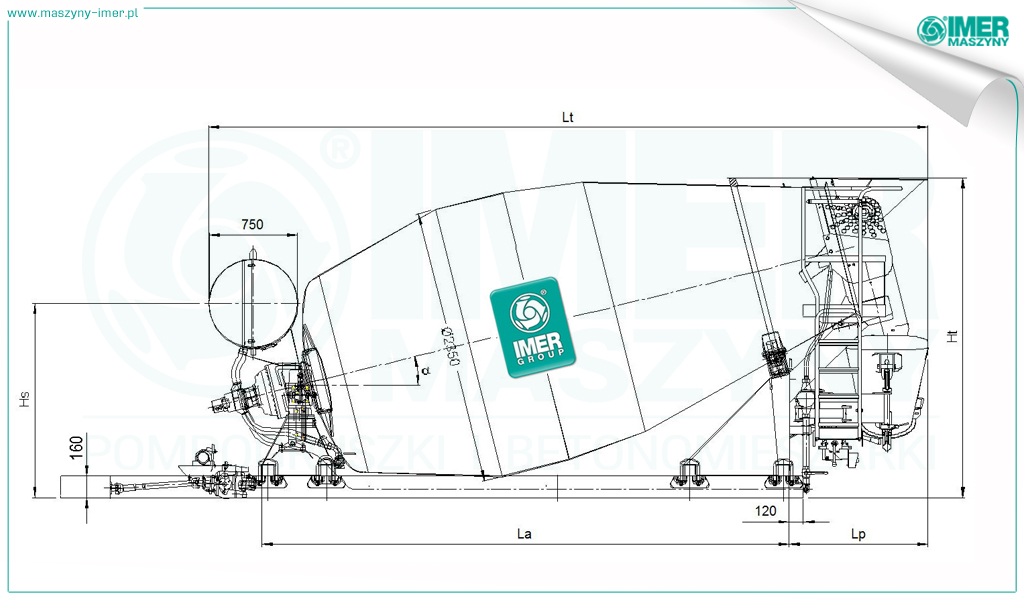

The most popular LT 9.7H concrete mixer with a nominal volume of 9m3 is a compromise between capacity and weight. Specially designed spiral and shovels, optimise the loading and unloading process and ensure the homogeneity of the concrete. We have designed the components of the concrete mixer to achieve the best geometry and to ensure maximum efficiency and functionality during the loading phase, minimising the risk of plugging the hopper section. Of course, safety as well as operator convenience have not been overlooked. The concrete mixer body is available in standard and superlight versions.

In the standard version, the drum walls are made of abrasion-resistant 30MnB5 steel with a thickness of 4mm. The same steel is used for the mixing spirals. In the SL version, on the other hand, the walls are made of IMER WEAR Raex 300 steel with a thickness of 3mm and the spirals of IMER WEAR Raex 450. This has reduced the weight by more than half a tonne. The drum is rotated by a two-stage planetary gearbox, which is driven by a variable displacement hydraulic pump. Oil is cooled by a powerful radiator with a built-in reservoir. The body has a pressurised steel water tank with a capacity of 400 or 650l. The water system additionally has a water meter with a scale from 0 to 500 litres.

Technical data:

Version H

Nominal volume 9 m3

Geometric capacity 16.048 m3

Installation height 2733 mm

Min. overall length 6558 mm

Min. installation width 2500 mm

Bowl speed 0-14 rpm

Discharge capacity 15 – 40 s/m3 depending on the consistency of the concrete

Weight (empty) 4200 kg, SL version 3599 kg

Running gear 8×4

Rollers: number 2 – diameter 280 mm

Standard equipment:

PMP two-stage planetary gearbox

Variable displacement hydraulic pump PMP

Oil cooler with integrated tank and filter, thermostat with electric fan

Mechanical (cable) speed control / direction of rotation of the concrete mixer

GAS+, GAS-, START, STOP motor control, safety switch on the back of the mixer

Auxiliary control on the back of the mixer: acoustic signal

Work lights – 4 pieces (2 pieces on the beam of the rear lights, 1 piece mounted under the platform, 1 piece on the platform-handrails – illuminating the hopper)

Reversing camera

180° rotating chute L=1500 mm with support and screw jack for angle adjustment

2 lightweight plastic (polystone) extension chutes with L=1000 brackets

Wear-resistant protective sheet on the main chute, hopper and rotary hopper

Rubber collar for inlet-hopper and V-discharge hopper

Telescopic ladder with platform and gate

400/650 l pressurised steel water tank

Pressurised water system

Water connection for filling the tank on both sides

Water meter 0-500 l

Washing hose at the base of the ladder and at the inspection platform

Single-axle polymer mudguards with mud flaps

Protection-cover between the frame beams

Standard rear bumper with steps on both sides for the operator

Technical data:

Version H

Nominal volume 9 m3

Geometric capacity 16.048 m3

Installation height 2733 mm

Min. overall length 6558 mm

Min. installation width 2500 mm

Bowl speed 0-14 rpm

Discharge capacity 15 – 40 s/m3 depending on the consistency of the concrete

Weight (empty) 4200 kg, SL version 3599 kg

Running gear 8×4

Rollers: number 2 – diameter 280 mm

Standard equipment:

PMP two-stage planetary gearbox

Variable displacement hydraulic pump PMP

Oil cooler with integrated tank and filter, thermostat with electric fan

Mechanical (cable) speed control / direction of rotation of the concrete mixer

GAS+, GAS-, START, STOP motor control, safety switch on the back of the mixer

Auxiliary control on the back of the mixer: acoustic signal

Work lights – 4 pieces (2 pieces on the beam of the rear lights, 1 piece mounted under the platform, 1 piece on the platform-handrails – illuminating the hopper)

Reversing camera

180° rotating chute L=1500 mm with support and screw jack for angle adjustment

2 lightweight plastic (polystone) extension chutes with L=1000 brackets

Wear-resistant protective sheet on the main chute, hopper and rotary hopper

Rubber collar for inlet-hopper and V-discharge hopper

Telescopic ladder with platform and gate

400/650 l pressurised steel water tank

Pressurised water system

Water connection for filling the tank on both sides

Water meter 0-500 l

Washing hose at the base of the ladder and at the inspection platform

Single-axle polymer mudguards with mud flaps

Protection-cover between the frame beams

Standard rear bumper with steps on both sides for the operator