Sales office and service Gdansk: +48 58 320 13 05 | Sales office Warsaw: +48 504 060 713 | PL | EN

Sales office and service Gdansk: +48 58 320 13 05 | Sales office Warsaw: +48 504 060 713 | PL | EN

Imer Machinery >> Imer Truck Mixers >> ORU LT 12XL.7H + SL version

Imer Truck Mixers ORU LT 12XL.7H + SL version

Do you want to transport 12m3 of concrete and maintain the maneuverability of an 8×4 chassis? The Imer LT 12XL.7H concrete mixer with a nominal capacity of 12m3 will be suitable for this purpose. It is a solid machine for large construction sites. Optimized drum geometry and special design of mixing spirals, as well as additional low-weight equipment result in low weight of the concrete mixer structure. A load capacity of up to 12 m3 of concrete can be achieved in combination with 4-axle chassis. The chute rotates up to 180°, together with the hydraulic angle adjustment, which will definitely facilitate the operator’s work. The concrete mixer body is available in standard and superlight versions

In the standard version, the drum walls are made of abrasion-resistant 30MnB5 steel with a thickness of 4mm. The same steel is used for the mixing spirals. In the SL version, on the other hand, the walls are made of IMER WEAR Raex 300 steel with a thickness of 3mm and the spirals of IMER WEAR Raex 450. This has reduced the weight by more than 800 kilograms. The drum is rotated by a two-stage planetary gearbox, which is driven by a variable displacement hydraulic pump. Oil is cooled by a powerful radiator with a built-in reservoir. The body has a pressurised steel water tank with a capacity of 400 or 650l. The water system additionally has a water meter with a scale from 0 to 500 litres.

The concrete mixer bodies are standardly equipped with a 180-degree rotating chute, and its inclination angle is adjusted using a manual hydraulic lift. The manufacturer also supplies two lightweight extension gutters made of plastic. The drum is equipped with a manual lock to prevent rotation. After blocking the drum, the interior can be inspected through the inspection hatch located in the side wall. A foldable ladder with a platform is used to control the load. There is a hose for washing the machine at the base of the ladder. Steel surfaces are shot-peened in SA 2.5 grade. Then two layers of anti-corrosion paint are applied. The machine is driven by the power take-off from the truck engine.

Imer Truck Mixers ORU LT 12XL.7H + SL version

Do you want to transport 12m3 of concrete and maintain the maneuverability of an 8×4 chassis? The Imer LT 12XL.7H concrete mixer with a nominal capacity of 12m3 will be suitable for this purpose. It is a solid machine for large construction sites. Optimized drum geometry and special design of mixing spirals, as well as additional low-weight equipment result in low weight of the concrete mixer structure. A load capacity of up to 12 m3 of concrete can be achieved in combination with 4-axle chassis. The chute rotates up to 180°, together with the hydraulic angle adjustment, which will definitely facilitate the operator’s work. The concrete mixer body is available in standard and superlight versions

In the standard version, the drum walls are made of abrasion-resistant 30MnB5 steel with a thickness of 4mm. The same steel is used for the mixing spirals. In the SL version, on the other hand, the walls are made of IMER WEAR Raex 300 steel with a thickness of 3mm and the spirals of IMER WEAR Raex 450. This has reduced the weight by more than 800 kilograms. The drum is rotated by a two-stage planetary gearbox, which is driven by a variable displacement hydraulic pump. Oil is cooled by a powerful radiator with a built-in reservoir. The body has a pressurised steel water tank with a capacity of 400 or 650l. The water system additionally has a water meter with a scale from 0 to 500 litres.

The concrete mixer bodies are standardly equipped with a 180-degree rotating chute, and its inclination angle is adjusted using a manual hydraulic lift. The manufacturer also supplies two lightweight extension gutters made of plastic. The drum is equipped with a manual lock to prevent rotation. After blocking the drum, the interior can be inspected through the inspection hatch located in the side wall. A foldable ladder with a platform is used to control the load. There is a hose for washing the machine at the base of the ladder. Steel surfaces are shot-peened in SA 2.5 grade. Then two layers of anti-corrosion paint are applied. The machine is driven by the power take-off from the truck engine.

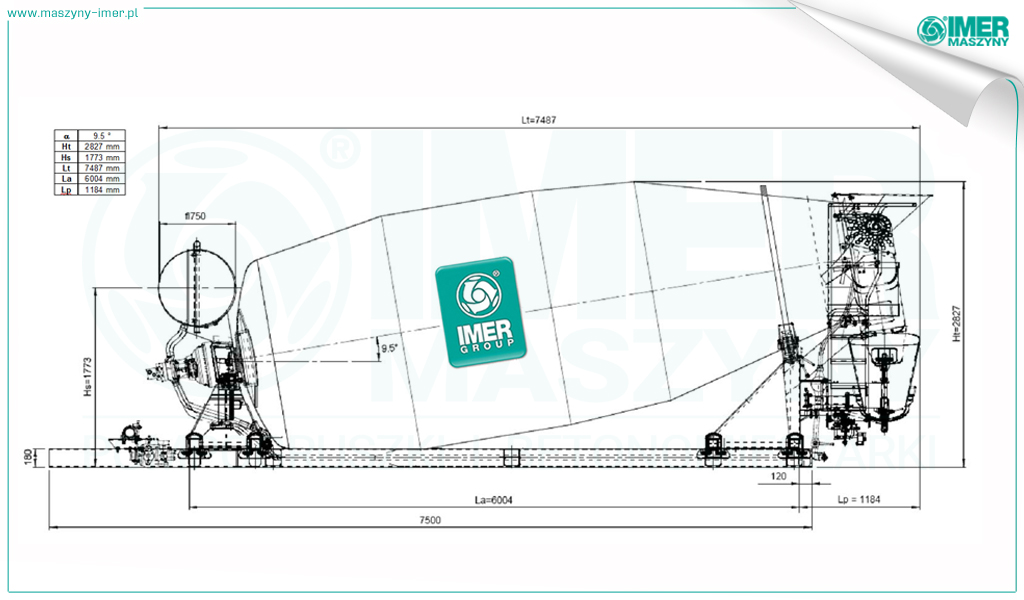

Technical data:

H version

Nominal capacity 12 m3

Geometric capacity 19,931 m3

Installation height 2827 mm

Min. construction length 7487 mm

Min. construction width 2500 mm

Drum speed 0-14 rpm

Unloading capacity 15 – 40 s/m3 depending on the consistency of concrete

Weight (empty) 4900 kg, SL version 4050 kg

8×4 chassis

Rolls: quantity 2 – diameter 280 mm

Standard equipment:

PMP two-stage planetary gearbox

Variable displacement hydraulic pump PMP

Oil cooler with integrated tank and filter, thermostat with electric fan

Mechanical (cable) speed control / direction of rotation of the concrete mixer

GAS+, GAS-, START, STOP motor control, safety switch on the back of the mixer

Auxiliary control on the back of the mixer: acoustic signal

Work lights – 4 pieces (2 pieces on the beam of the rear lights, 1 piece mounted under the platform, 1 piece on the platform-handrails – illuminating the hopper)

Reversing camera

180° rotating chute L=1500 mm with support and screw jack for angle adjustment

2 lightweight plastic (polystone) extension chutes with L=1000 brackets

Wear-resistant protective sheet on the main chute, hopper and rotary hopper

Rubber collar for inlet-hopper and V-discharge hopper

Telescopic ladder with platform and gate

650 l pressurised steel water tank

Pressurised water system

Water connection for filling the tank on both sides

Water meter 0-500 l

Washing hose at the base of the ladder and at the inspection platform

Single-axle polymer mudguards with mud flaps

Protection-cover between the frame beams

Standard rear bumper with steps on both sides for the operator

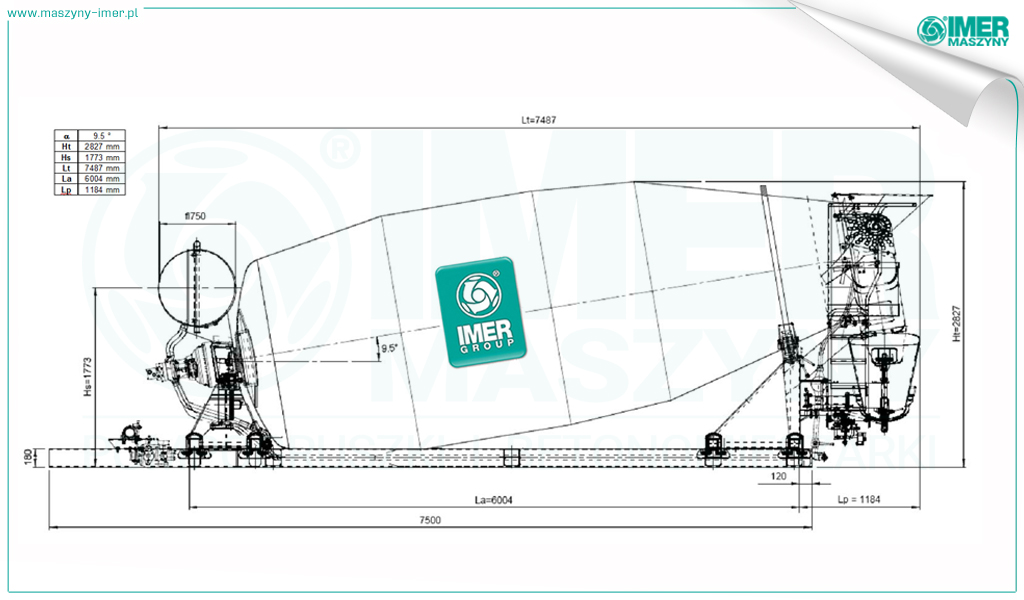

Technical data:

H version

Nominal capacity 12 m3

Geometric capacity 19,931 m3

Installation height 2827 mm

Min. construction length 7487 mm

Min. construction width 2500 mm

Drum speed 0-14 rpm

Unloading capacity 15 – 40 s/m3 depending on the consistency of concrete

Weight (empty) 4900 kg, SL version 4050 kg

8×4 chassis

Rolls: quantity 2 – diameter 280 mm

Standard equipment:

PMP two-stage planetary gearbox

Variable displacement hydraulic pump PMP

Oil cooler with integrated tank and filter, thermostat with electric fan

Mechanical (cable) speed control / direction of rotation of the concrete mixer

GAS+, GAS-, START, STOP motor control, safety switch on the back of the mixer

Auxiliary control on the back of the mixer: acoustic signal

Work lights – 4 pieces (2 pieces on the beam of the rear lights, 1 piece mounted under the platform, 1 piece on the platform-handrails – illuminating the hopper)

Reversing camera

180° rotating chute L=1500 mm with support and screw jack for angle adjustment

2 lightweight plastic (polystone) extension chutes with L=1000 brackets

Wear-resistant protective sheet on the main chute, hopper and rotary hopper

Rubber collar for inlet-hopper and V-discharge hopper

Telescopic ladder with platform and gate

650 l pressurised steel water tank

Pressurised water system

Water connection for filling the tank on both sides

Water meter 0-500 l

Washing hose at the base of the ladder and at the inspection platform

Single-axle polymer mudguards with mud flaps

Protection-cover between the frame beams

Standard rear bumper with steps on both sides for the operator